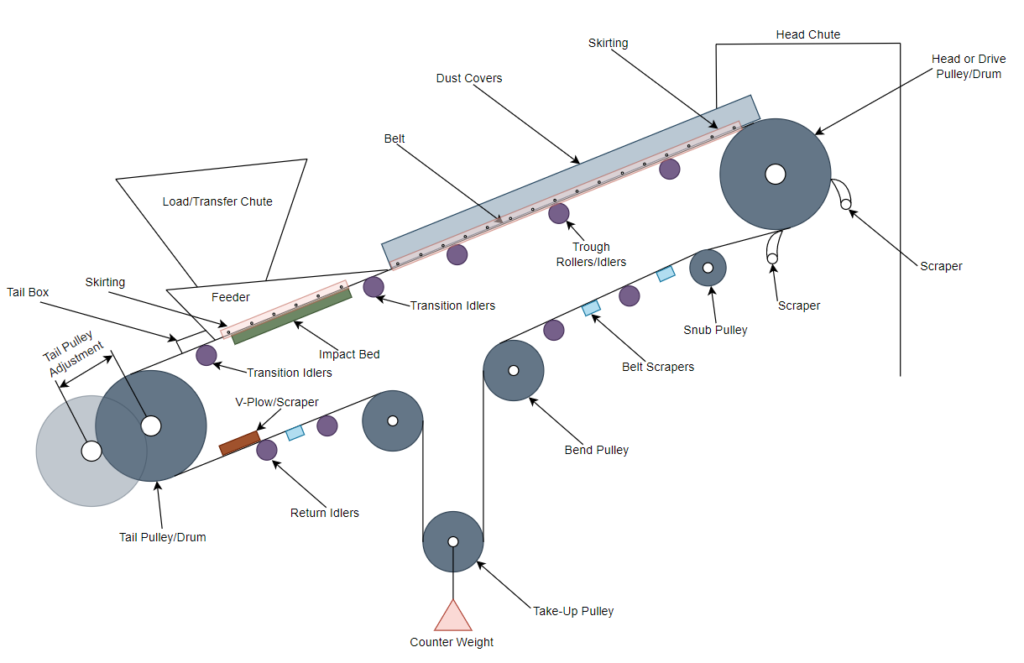

Common Conveyor Components

Head or Drive Pulley – Typically used to drive the conveyor belt, and generally mounted on external bearings (e.g. pillow block bearings) and rotated via a hydraulic or electric motor mounted onto the shaft and conveyor frame.

Take-Up Pulley – Commonly used on longer conveyor lengths to take up slack and increase conveyor belt tension.

Bend Pulley – Redirects the conveyor belt and increases tension.

Return Idlers – Redirects conveyor belt back to tail pulley and helps form the shape of the belt system.

Snub Pulley – Increases the surface area of belt contacting the head pulley, thereby increasing the traction of the belt on the pulley.

Tail Pulley – Redirects the belt back to the head drum. Commonly serves the purpose of the take-up pulley on shorter conveyor lengths which is achieved via using adjustable mounts on the tail pulley.

Belt Scrapers – Clean the belt and sometimes serve the purpose of return idlers as well.

Transition Idlers – Gradually forms the U – shape of the belt to the desired trough angle.

Trough Idlers – Maintain the U – shape of the belt which increases the overall carrying capacity of the belt.

V-Plow Scraper – Helps clean the underside of belt.

Head Chute – Directs material to desired location.

Feeder – Directs and contains incoming material onto the conveyor belt.

Skirting – Helps prevent material spillage.

Dust Covers – Often used to prevent spillage and light weight material being blown off belt.

Impact Bed – Absorbs impact of material being loaded onto conveyor, and helps prevent damage to the belt.

This diagram above shows common components most conveyors will share, however each conveyor will be different and won’t include all the components shown or will have extra components that are not shown.